The Role of Modern Technology in Modern Welding Inspection Madison Practices

The Role of Modern Technology in Modern Welding Inspection Madison Practices

Blog Article

Recognizing the Basics of Welding Evaluation to Guarantee Quality and Safety

In the realm of modern-day design, welding evaluation stands as a cornerstone for ensuring both the top quality and safety and security of architectural productions. The procedure involves a meticulous evaluation of bonded joints, utilizing sophisticated techniques such as ultrasonic and radiographic testing to spot surprise blemishes. The expertise of qualified examiners is important, as they bridge the space in between theoretical standards and practical application. Their role extends past simple detection, including the documents and interaction of findings to pertinent stakeholders. What are the subtleties of these evaluation approaches that make them vital for preserving architectural integrity?

Significance of Welding Evaluation

In the world of industrial fabrication, the relevance of welding assessment can not be overstated. Welding inspection plays an essential role in ensuring the honesty, security, and longevity of welded frameworks (Welding Inspection Madison).

The procedure of welding inherently entails intricate variables, including temperature, product residential or commercial properties, and environmental problems, all of which can influence the top quality of the weld. A complete assessment identifies issues such as fractures, porosity, and incomplete fusion, which can jeopardize the strength and integrity of the weld. By identifying these problems early, corrective actions can be taken, thereby lowering the risk of failure and linked prices.

Furthermore, welding inspection adds to regulative conformity, as many markets are governed by stringent safety and security requirements and standards. Failure to follow these guidelines can result in legal responsibilities and monetary fines. Ultimately, welding evaluation not only safeguards physical frameworks yet also secures human lives and promotes sector credibilities.

Trick Welding Inspection Techniques

Although welding inspection is essential to making certain the high quality and safety of welded frameworks, it is the particular methods used that figure out the effectiveness of the inspection process. Key welding evaluation methods can be generally categorized right into non-destructive testing (NDT) and destructive screening.

Magnetic fragment testing and fluid penetrant screening are surface examination techniques made use of to find surface and near-surface flaws. These comprehensive examination approaches ensure that welds meet industry requirements and safety and security requirements, thus making sure architectural honesty and efficiency.

Duty of Qualified Assessors

Certified assessors play a pivotal role in the welding inspection process, guaranteeing that all welds abide by strict market standards and safety policies. Their proficiency is vital in determining problems or irregularities that may compromise the architectural honesty of a weld. By diligently checking out each weld, licensed examiners help avoid potential failings that can cause expensive repair work or dangerous crashes.

To come to be licensed, inspectors have to go through rigorous training and screening, which familiarizes them with various welding strategies, materials, and testing techniques. This detailed knowledge permits them to examine weld high quality successfully and make educated judgments about their safety and security and dependability. Furthermore, qualified examiners excel in translating specs and blueprints, making sure that the welding job lines up with the project's style requirements.

An important component of their duty is to record their searchings for thoroughly, providing a comprehensive record of the assessment procedure. Their contribution is important in preserving high levels of high quality and security in welding operations.

Tools Used in Welding Inspection

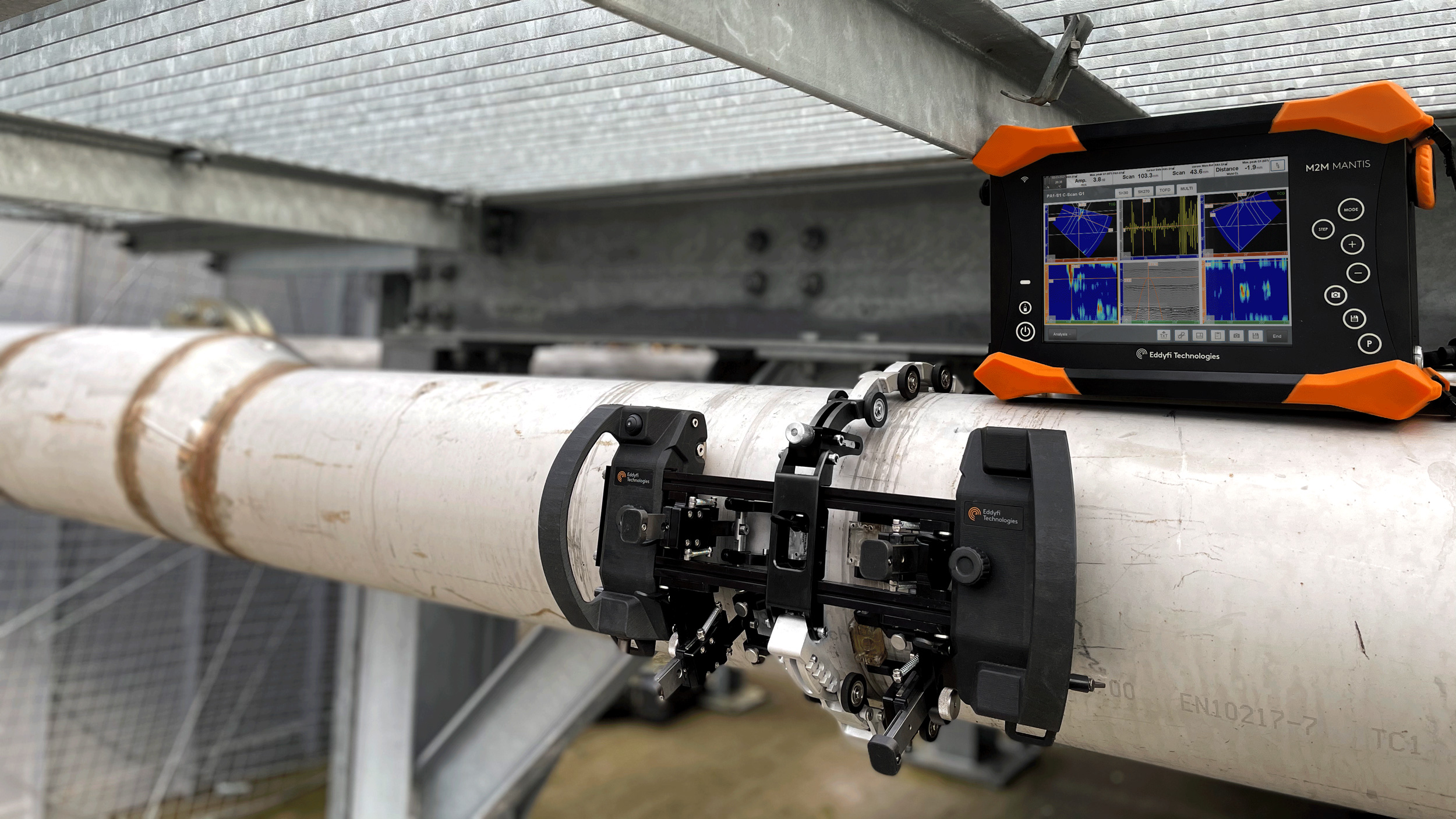

Welding inspectors rely upon a selection of specialized devices to perform their responsibilities effectively, ensuring each weld fulfills the needed requirements. Among these devices, aesthetic evaluation aids like original site multiplying glasses and mirrors are essential, allowing assessors to carefully analyze welds for surface issues such as splits, porosity, and undercut. Calipers and fillet weld assesses are vital for measuring weld measurements to verify conformity with design requirements.

Advanced tools extend past visual help, including non-destructive screening (NDT) devices. Ultrasonic testing tools are critical in spotting subsurface flaws, using sound waves to expose internal stoppages without jeopardizing the weld's honesty. Radiographic testing utilizes X-rays or gamma rays to record pictures of a weld's inside, highlighting potential problems.

Magnetic fragment testing is an additional vital device, particularly for identifying surface and near-surface interruptions in ferromagnetic products. By applying electromagnetic fields and ferrous bits, inspectors can determine flaws that might otherwise be unseen.

Dye penetrant inspection is typically made use of for non-ferrous products, offering a contrast-enhanced aesthetic look for surface-breaking issues. Welding Inspection Madison. With each other, these tools enable welding examiners to thoroughly examine weld top quality, guaranteeing security and reliability in different applications across markets

Making Sure Architectural Honesty

Welding procedures have to stick to established criteria and codes, such as those specified by the American Welding Culture (AWS) or the International Organization for Standardization (ISO) These standards make certain that the welds can stand up to operational anxieties and environmental factors. Certified and certified welders play a critical function in this procedure, as their experience makes sure that strategies are applied appropriately, reducing flaws such as cracks, porosity, and insufficient blend.

Post-weld evaluation is an additional important element of validating structural stability. Non-destructive testing (NDT) approaches, consisting of ultrasonic testing and radiographic testing, are employed to identify subsurface imperfections without compromising the welded framework. These inspections verify that the welds meet the needed quality standards, offering guarantee of their resilience and integrity. Inevitably, ensuring structural stability in visit welding not only safeguards human lives but additionally safeguards financial investments and boosts the long life of engineered structures.

Conclusion

The basics of welding examination are crucial for preserving the high quality and security of bonded structures. The use of specialized devices further boosts the examination procedure, eventually securing human lives and lengthening the life expectancy of welded buildings.

Welding assessment plays a critical role in guaranteeing the honesty, safety and security, and longevity of welded structures.Although welding evaluation is crucial to making sure the high quality and security of bonded frameworks, it is the particular techniques utilized that establish the effectiveness of the examination procedure. Secret welding assessment techniques can be broadly categorized into YOURURL.com non-destructive testing (NDT) and devastating screening.Certified inspectors play a critical duty in the welding evaluation process, guaranteeing that all welds comply with rigorous sector requirements and safety and security guidelines.The fundamentals of welding examination are crucial for keeping the quality and safety and security of bonded structures.

Report this page